Demystifying the World of Materials: The Impact of Compression Testing Machines

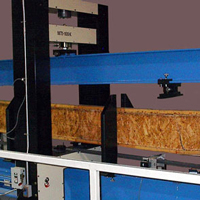

In the realm of materials testing, where precision and reliability are paramount, compression testing machines emerge as unsung heroes. These sophisticated devices play a pivotal role in assessing the compressive strength and characteristics of various materials, providing invaluable insights for industries ranging from construction to manufacturing. This blog delves into the world of compression testing machines, exploring their significance, functionalities, and the impact they have on ensuring the integrity of materials. Understanding Compression Testing: The Core Principle: At its essence, compression testing involves subjecting a material to a controlled force applied in a direction perpendicular to its surface. This force, often delivered by a hydraulic or electromechanical system, allows researchers and engineers to measure how well a material withstands compressive stress. Importance in Material Evaluation: The ability to withstand compression is a cr...